July 2024:

Here was to be the final instalment of the Treadwell build 😀

Recent work has been mostly focused on making the sledge to transport WED on, via the cars roof rack.

Sounds:

Needed to fit a speaker and wasn’t happy with my original position idea. So decided to fit in inside the ‘logic housing’.

Position located:

I had added longer leads from it to reach the amplifier board.

Just need to finish off some connections and save some sound files. Keep forgetting these last two pieces. Needed to buy a proper servo controlled switch, similar to the one used in R5, but this ones a single and much smaller.

Another tweak, was the addition of a volume (potentiometer) to boost the sound. When I couldn’t hear it at Mshed event, I knew I had to install one.

3D printed the knob from a file on the Prusa printables website.

Had to rewire the signal to volume dial to amp to speaker wires.

Claw arm servo:

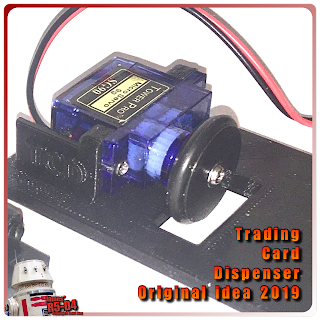

The new micro servo arrived sooner than expected lol, but I had already started on a modified 3D printable housing to fit a new metal geared SG90 size servo. It didn’t take up much more space , but i had to reposition the securing screw, and add a second one.

I used brass knurled threaded inserts & M3 screws.

I made a slot in the side to allow the servo horn some freedom. This once finished, could be covered.

I needed to add a slot in the claws tube to allow some flexibility for the wire that connects to the servo horn.

Next was to remove the servo plug so that it could connect with the servo lead.

Almost forgot about painting it…..

Weathering:

Dug out the paints and got to adding brown, yellow and ochre.

Then black to give the dirty oily look.

At the Mshed event, I was asked by some of the builders if Tread was metal construction, they were surprised to hear the upper section was all 3D printing.

Upgrades:

I know I said this was going to be the last post on this build, but I have a few more tweeks to do with things I wasn’t happy with, so there’s more to come.

July 25th…….

Wheels:

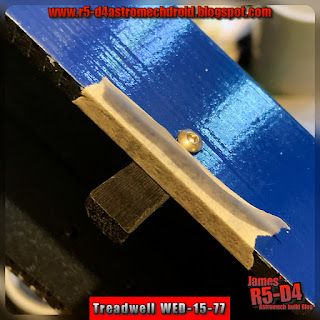

The original wheels were spaced away from the base, as can be seen in these two photo.

|

| original deleted scene SW ANH |

|

| remade version for the prequals |

So I decided to draw up some spacers and 3D printed them. This along with some more substantial axle bushes with bearings in, to better support and properly align the wheels. And finally, some new axle's at over 180mm in length!