🎉 Welcome to 2023 🎉

- New servos

- Claw Arm & Carbon fibre rods

- 3D printed hose clips

- Mast update

- Ordered some filler primer paint

New head/eye servo:

One for the eyes. I’ve also redrawn up the piston part of it. The linkage between the two eyes has also been modified.

Claw arm:

Back in work Jan 4th, and drew up first arm bracket that attaches to the mast. Printed it off to see how it will work. Am impressed lol, it looks good and is functional to, the arms pivot well & the test ‘tube’ slides well in the lower ‘piston’.

Here’s some pictures of the CAD work, inc half section views.

The end unit which the Claw fits into has been redesigned/updated. It now looks more like Paul6700's. I've also been working on a way to get the Claw to operate as well. Had to 3D print off a small adaptor, which then attaches to a spring, more on this in a later Blog post, when I actually get it all working lol.

Here’s a test assembly:

The steel tube (in above picture) will be replaced with the carbon fibre tube (before it arrived). This will help with the weight for the servo to lift the assembly.

Took me a few attempts to figure out how best to actuate the movement, but I think I have a working idea.

Hose Clips:

I drew up & 3D printed off some hose clips. These can be seen on the original version. The original was operated by hydraulics', but not knowing what they actually used, I drew these up to just clip over (to be eventually glued) in place to hold the 'hydraulic' hose.

Mast:

The last lower sections of the Mast have not been printed yet. Before they get glued together, there are details that need to be included & holes to be cut.

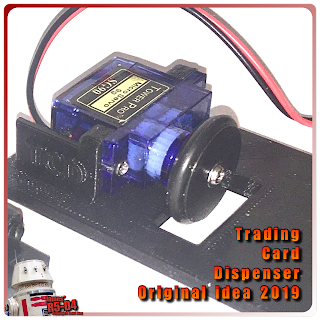

Drew up and printed off a SG90 mini, servo bracket. This will be housed inside the mast, hopefully to actuate the claw.

Filler primer paint:

Visited my local car store (Halfords UK), and the price for one can was £10!

So I went on eBay and bought two (better) can's for the same price!