Droid Builder

Extra Projects & Event Page's

- Home

- Trading Card Dispenser (NEW version 3) - TCD [2020/2022]

- Trading Cards

- R5-D4's ....Bad Motivator development

- R5-D4 - silver neck details

- R4-D4 - Dome [wood build]

- R0-D4 Dome [wood build]

- 3D Printing

- *** Star Wars Shoes ***

- GOUD-4 Messenger Droid - Solo ASWS

- Event: Mshed Bristol 2025

- Event: Mshed Bristol 2024

- Event's 2018

- Event's 2017

- Event 2016 - "Celebration Europe"

- Event's 2015

- Event 2014 - Chippenham Sci-Fi

- R5-D4 - events page - The beginning (2013)

- ** R5-D4 patch **

- R5-D4 Photos

- Costume for my Son - Han Solo -

- Costume for my Son - Boba Fett

- Droid Caller - Han Solo style

- Scanning Crew Container - Transmitter Storage Box

- Stormtrooper - me

- Rogue One - trading card storage box

- Rogue One

- Jabba’s gate prop for Celebration 2023

- Treadwell Droid - WED-15-77

May 04, 2022

Happy to help fellow builders: ROJO CINCO DROIDS

April 12, 2021

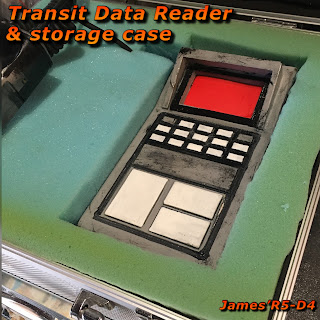

Transit Data Reader - for R5-D4's Utility Arm Socket screen (Part 2)

March 17, 2021

Transit Data Reader - for R5-D4's Utility Arm Socket screen (Part 1)

February 23, 2021

Utility arm UPPER socket screen (Part 4)

December 16, 2020

Utility arm UPPER socket screen (Part 3)

Test fitting of the panel identified that a few things needed tweaking.

- The utility arm wouldn’t close properly.

- The screen was still a bit tight.

December 15, 2020

Utility arm UPPER socket screen (Part 2)

Before spaying up the screen white & then getting to work on weathering it.....see below.

The piece of wood that sits between the two utility arms, needed to be thinned down for the screen to fit. My original measurement was for a snug fit, but the print was just a bit higher than expected, so rather than take a blade to the 3D screen print (loosing details) I decided to trim the wood piece. This then needed some wood filler before repainting. It was black and I did respray it matt black again, but am thinking white so it all blends together.....

Once all dryer I’ll start weathering this piece and the screen before re-installing.

December 11, 2020

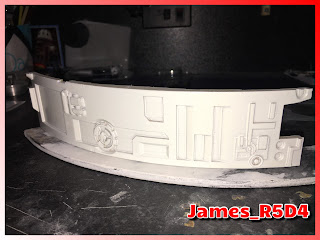

Utility arm UPPER socket screen

I made a design change to remove the opening for the Trading Card Dispenser, and some other alterations so it differed from the lower screen.

Started the print Sunday afternoon around 3pm (UK time), layer height of 0.4, and it eventually finished Monday morning 9am (UK) lol. 17hrs 39mins.

I had supports on but only touching build plate.... I think?? So apart from one ‘not seen area’ the print came out great!

Not sure if bed or extrusion needs adjusting as I get this on the first few layers of the print. Nothing a knife can’t sort but still lol. It was extrusion, wasn’t hot enough for the initial layers.

After cleaning up work, it was time for primer/filler painting. Once dried, a bit more cleaning up before top coat.