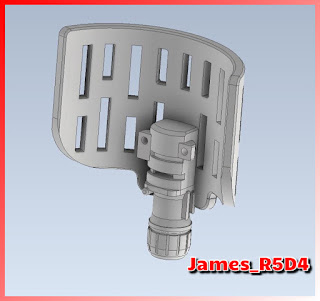

After the test fitting of the servo, I was able to better define what was/wasn’t needed and what changed I needed to make. Some of these were just for aesthetics, others to better suit the servo and positioning of it.

These included:

- Adding a small slot to one of the front grooves to allow the servo location tab to slot into. Just to add a bit to secure it.

- Moving the position of the servo further forward towards the centre of the scanner.

- Simplifying and standardising the design a bit more.

Next up was to design up a coupler for the servo to connect with the aluminium tube that arrived today.

This will use the servo screw to secure it and then the coupler will be a push fit onto the tube.

After printing and test fitting, I had to concede that this servo was actually TO small :D never mind....... onto plan B.

As I know that the servo attachment fitted onto the aluminium tube, I redesigned the outer surfaces and combined them into one file.

I've already got a lift system idea, and have some electrical/electronics to get together. So planning and building work continues.

And the printing has begun...

Hour and a half into the print gets you this far lol, 0.1 layer height.

No comments:

Post a Comment