For my Wood internal wheel frame, I used T-nuts to be able to clamp the leg ankle to the foot internal. This was a great idea as it ment I didn't have to (somehow) reach inside and try to secure the bolt to the nut.

Now I have metal frame work, this requires I get a nut welded to the back face.

Here is the finished frame, just need cleaning up the weld splatter. Thanks Dave, great work!

Aluminium angle and bolts can now be removed.

I will need to cover/fill/block up the threaded holes visible inside the side channel plates.

I also needed to re-drill a hole location for the lower aluminium channel plate.

One was a new hole due to the location of the new metal frame internals and the old hole would need to be blocked up. So I decided to just make up a new strip as the old version I wasn't to happy with how it looked or would of looked with the blocked hole.

So I drilled & countersunk two new holes.

Secured with these hex socket countersunk bolts off eBay :)

Sorted out the axel bolt holes and reduced the brass motor bolt bush's my 1.6mm.

This helped alignment of the belt with the wheel more.

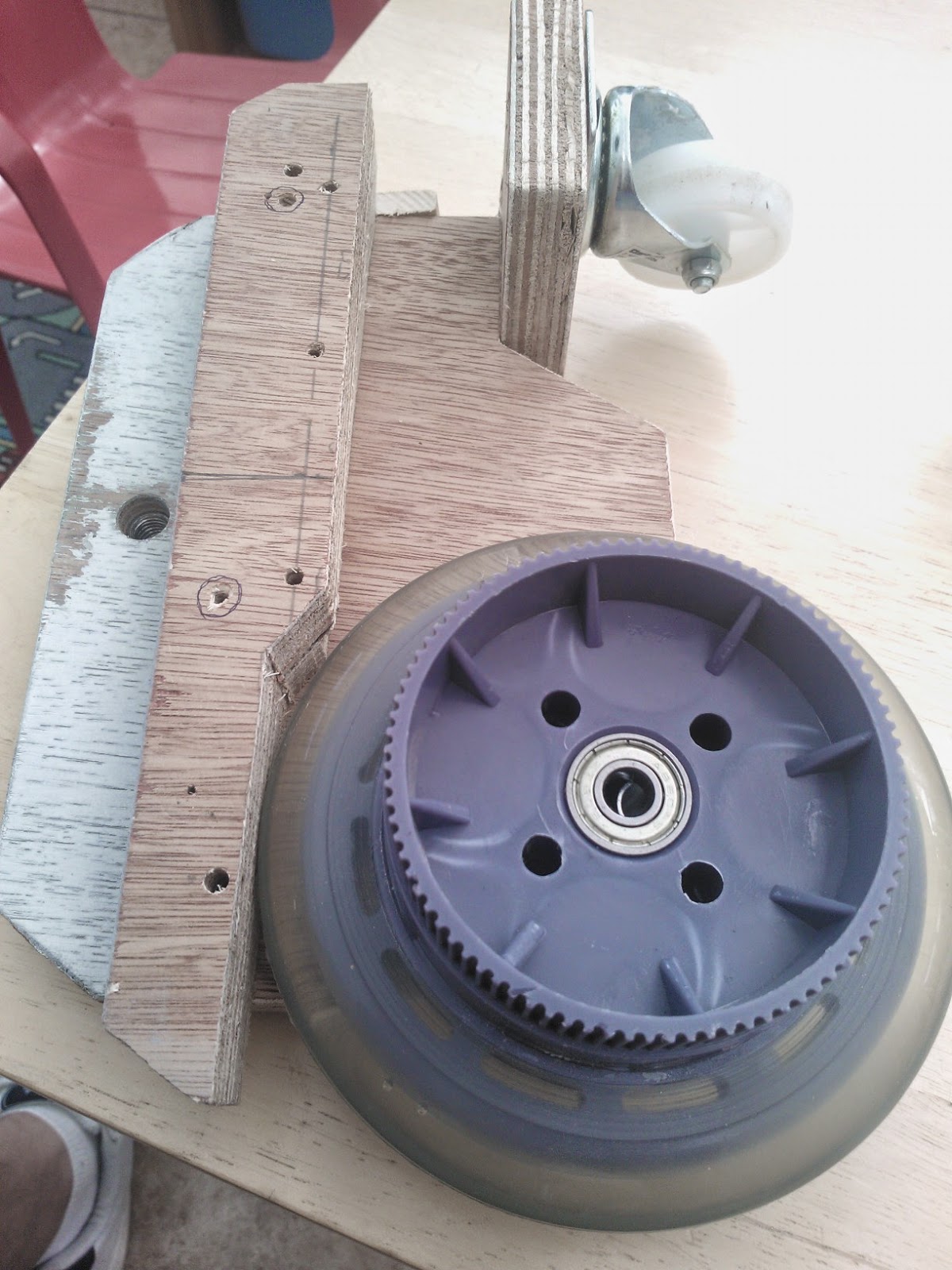

Next up is to fix the front caster back on. This is a stabiliser to keep the foot level.

Measured up the inside, this is bacause the metal flexed a bit when it was welded.

These are just gude measurements ;-) lol

Next is to fit the front caster on, then it's on with frame work for Outer Foot No2.