With the new addition of the SyRen10 dome speed controller, I wanted the main control panel to be self contained. As I originally (due to time/space) had the 24v to 12v converter mounted on the sound board.

I wanted it tho to be independent, so with the panel out of R5's body, I got to work on re-working the layout to fit it all on.

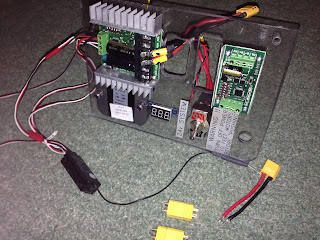

R5's Power control panel

Waiting on a few connector blocks and then connecting it all back up again.

So connectors came, heat shrink, cables & terminal block too. Any free time I spent on cutting, soldering (all connectors, non of this crimped stuff going on here!) then heat shrinking everything in sight lol.

Found a double sided sticky pad, for the transmitters receiver, to mount it on the panel.

So connectors came, heat shrink, cables & terminal block too. Any free time I spent on cutting, soldering (all connectors, non of this crimped stuff going on here!) then heat shrinking everything in sight lol.

Found a double sided sticky pad, for the transmitters receiver, to mount it on the panel.

The front view.

And part of the rear, view.

I say part, as the feet switch and cables are still inside R5's body, connected up. The switch goes in the hole next to the 'WARNING' label.

Next was to reinstall it back in place, wire up and test. The lead for the dome & the transmitter power were moved around. Power in was shown in the picture as channel 3, now in channel 6 socket - power. And the lead for the dome was moved to channel 4.

This is so that the left hand transmitter stick, auto centers after use.