😄😄😄 lol, yes…..aaaaaand no.

Back in April (last month)….

R5’s ride height has always been an annoyance for me over the years. Most noticeably at events on nice flat surfaces where I can clearly see the wheels. [for film appearance's 😎, this isn't so much of an issue]

Also the feet internals weigh quite a bit and they don’t support the floating foot shells very well.

So, I decided I needed to redo them to be lighter and lower.

Using my original internal feet frames, I drew the new versions up in AutoCAD inventor and then 3D printed out these test pieces.

This build structure is not new, but as buying the components might not fit my 'UNIQUE' foot shells, designing my own to fit made sense.

Above is first draft printed. The cut outs were just to save filament.

Test fit inside the foot shell.

And showing the reduced protrusion from the bottom of the shell.

I’ve ordered some aluminium plate, for the frames off eBay.

The first sheet of metal arrived.

Due to a family event, the funeral of my Grandmother who reaches 105years, the project was paused.

May 2022

Tuesday 3rd: was cutting aluminium plate day. I got out a hacksaw and started cutting out the main side plates.

I was also figuring out bolts, spacers and nuts.

Additional plates are on order, the two hashed areas on the 3D prints [above picture] are not needed so will be removed.

Found some suitable Stainless Steel tube, which will be great as the spacers.

I’ll be using M6 bolts and Nylock locking nuts, which I bought from local DIY store.

The steel tubing needed to be squared off at the ends, so used the lathe.

The bolts have washers both ends and locking nuts.

I drew up a shell support to help keep it from tipping over, as the shell 'floats' on the inner frame. This I 3D printed off to save weight. It's held in place by the longer bolts, washers, nuts.

Next up was creating retaining clips for the aluminium channel strip. First idea was hollow, but thought, it doesn’t have to be. So cut it in half and turned it into a clip, that snaps over the spacer tubing.

With the new frame layout, it will also be easier for me to access the ankle bolts, nut. On the original steel frame, I had the nut welded in place. Now, I’ve got nylock flanged nuts.

Next was to drill location holes for the front caster mounting, angle plates. And I positioned the caster to be more inline with the rear wheel.

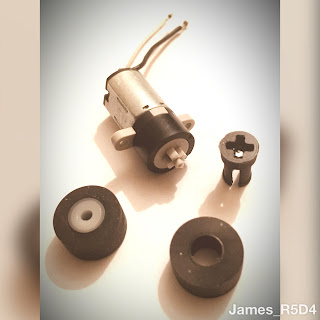

And here’s the completed assembly, with motor and caster fitted. This whole assembly is so much lighter than the old one.

I have already made a start on cutting out the second set of plates. So this will come in a following post.

June 2022

Back in work after a short break away and back on with cutting out plates for foot no2.

….a rushed week of getting everything sorted before attending Saturday 18th’s event at Stars of Time, in Swindon’s steam museum. But got everything installed Friday night lol.

Event report to follow…..