Masked off the back plate and cut out the segments to be sprayed with primer.

Ignor the off centre segment line markings. I corrected these in the shaded areas ;-).

Extra Projects & Event Page's

- Home

- Trading Card Dispenser (version 2) - TCD [2020/2022]

- R5-D4 - Trading Cards

- R5-D4 - silver neck details

- R4-D4 - Dome [wood build]

- R0-D4 Dome [wood build]

- 3D Printing - Star Wars stuff

- *** Star Wars Shoes ***

- GOUD-4 Messenger Droid - Solo ASWS

- Event's 2018

- Event's 2017

- Event 2016 - "Celebration Europe"

- Event's 2015

- Event 2014 - Chippenham Sci-Fi

- R5-D4 - events page - The beginning (2013)

- ** R5-D4 patch **

- R5-D4 Photos

- Han Solo - costume for my Son

- Droid Caller - Han Solo style

- Boba Fett - costume build for my Son

- Scanning Crew Container - Transmitter Storage Box

- Stormtrooper - me

- ROGUE ONE - trading card storage box

- Rogue One

May 31, 2011

Primer spraying components

My first bit of spraying! Primmer on 'ankle details' & 'octagon port' internal walls.

Ankle Details are not so smooth now lol.

Ankle Details are not so smooth now lol.

Ankle Details - ready for priming

R5-D4 Astromech figure - 'Vintage Collection'

Whilst out at the weekend, I popped into toys'r'us, like you do (without he kids, lol) & there, on the reduced section of the Star Wars figures rack for £4.49 was.......

I never had the original version, all those years ago. And i know it's not the 'stickered' version, but its nice to have, just the same :-) This is from the 'Vintage Collection'.

Front Vents...... update pt5

Top Vent almost finished. Finally got round to filing out the last rectangle slot. I need to file the edges to size and then it just needs glueing together. Next, the lower vent & internals.

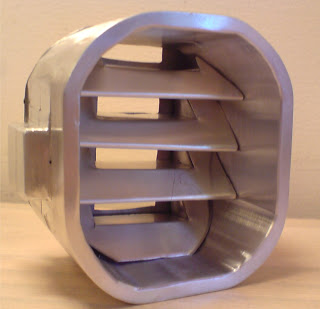

Octagon Port 1 construction centre piece pt2

Had spare five minutes and a free lathe, so machined up the other octagon ports center piece.

Thread tapped a hole in the back for location & fixing together.

Thread tapped a hole in the back for location & fixing together.

May 25, 2011

Octagon Port 1 construction UPDATE.....

Finished off bending the second plate up, for the other half of the wall surround. Depending on how R5's skin is constructed, will determin how much needs to be shaved off the Octagon's walls.

(As they should be curved to fit the diameter of R5's body).

Next I machined the centre diameter part. This has a screw thread in the back to secure it and the support bracket, which locates it onto R5's base.

The next part is to mask off the parts that need painting blue and after this, the parts will be glued, bolted together and secured to R5's base.

(As they should be curved to fit the diameter of R5's body).

Next I machined the centre diameter part. This has a screw thread in the back to secure it and the support bracket, which locates it onto R5's base.

The next part is to mask off the parts that need painting blue and after this, the parts will be glued, bolted together and secured to R5's base.

May 23, 2011

Octagon Port 1 construction begins

Lunchtime, I cut out the first two of the three [four] pieces, needed to make up my first Octogan Port. The back plate and one of the side pieces. I made this into two sections so as to be able to bend the angles correctly.

I also left enough to bend tabs for the back plate to attach too. I just need to cut out and bend to shape the second [piece 3] for the sides and then I need to machine up the centre diameter piece [piece 4].

I also left enough to bend tabs for the back plate to attach too. I just need to cut out and bend to shape the second [piece 3] for the sides and then I need to machine up the centre diameter piece [piece 4].

Save The Lars Homestead

Added this link to my page as, well, it's speaks for it's self really. They also have a Facebook page too.

A worthy cause and has the backing of Lucas Films too!

A worthy cause and has the backing of Lucas Films too!

May 20, 2011

Octagon Port construction

Had a few ideas about how to make up the Octagon Port units. The one I'm gonna try first is by making a flat rear plate and then a long strip, with bent angles to form the sides. I'm then going to machine up the central diameter piece and screw/bolt this to the back piece.

Vent internals - top

Did a bit more trimming of the Vent internals, till I was happy with the fit. Still need to finish off the back plate cutouts, and then it's time to glue it all together.

May 18, 2011

Front Vents - internals

I made cardboard templates, to scale, for use with makeing metal vent internals. As was looking at makeing the vents as one piece. Sloped part and back as one, bent to shap them. Used thinner material, easier to cut & bend to shape than the back plate.

Pictures will explain this better :-D

Cut out a piece of metal plate for back part of internals. Then marked up & drilled holes for the cut out's. These holes I will file to correct shape.

Pictures will explain this better :-D

|

| The cardboard version |

|

| The Vents cut out and bent roughly to shape |

|

| The Vents fitted over the cardboard template to check. |

Cut out a piece of metal plate for back part of internals. Then marked up & drilled holes for the cut out's. These holes I will file to correct shape.

|

| Rear Vent Plate |

Front Vents...... update pt4

Front Vent no1:

Last few days in work, I've been milling the vent surround. Milled away the outside of the prodruding part, to start the shape of the radius. Also on the hidden parts to reduce weight. Then filed the curved outside. It has taken a while, to complete the first Vent surround and I've learnt a lot, so hopefully the second vent surround will be a lot easier to make and I'll be able to make it quicker.

Heres the completed outside vent:

I dont think the pros got anything to worry about lol, but I'm happy :-)

Last few days in work, I've been milling the vent surround. Milled away the outside of the prodruding part, to start the shape of the radius. Also on the hidden parts to reduce weight. Then filed the curved outside. It has taken a while, to complete the first Vent surround and I've learnt a lot, so hopefully the second vent surround will be a lot easier to make and I'll be able to make it quicker.

Heres the completed outside vent:

I dont think the pros got anything to worry about lol, but I'm happy :-)

May 17, 2011

Vent story so far.....

I've been busy working on finishing off the top Vent. Rather than posting bits here and there, I'm trying to finish it off and then post up one big progress, with better quality pics, than previous ones.

Is looking good and shouldn't be too much longer now....... I hope lol.

Is looking good and shouldn't be too much longer now....... I hope lol.

May 10, 2011

Front Vents...... update pt3

Got a little bit more done today on the first top vent. First thing this morning I drilled out the rear part of the vent surround. Then on my lunch break I drilled, counter-sunk & thread tapped the two parts together. This is so that when it comes to milling the inside and outside, both pieces will be 'paired'.

Hopefully tomorrow I'll be able to machine out the insides.

|

| Two parts screwed together. |

May 09, 2011

Front Vents...... update pt2

YES!!!! Lunchtime, I got on with drilling out the centre part of the Front Vent. I'm happier now with it looking more like it should, just need to mill round the edges and then onto the back half.

Is now starting to look like a Front Vent.......... if you squint your eyes a bit, lol.

Is now starting to look like a Front Vent.......... if you squint your eyes a bit, lol.

R5's Ankle Detail

Front Vents...... update

did some more milling on the front vent after work on Friday. But due to the cutter sizes available, it is going to take ages to machine the centres out! :-(. Will have to drill more first & then mill to finish off.

So am now thinking of another way to make them, just in case lol.

So am now thinking of another way to make them, just in case lol.

May 06, 2011

Skins

Checked out price of 'budget skins' for R5. A member of astromech forum makes them and has very good feedback! Price is around the £60 mark, inc shipping from the USA, which i feel, would be worth it to make R5 look right! :-)

Shoulder Stabaliser out of wood.......

Bought some dowel in B&Q, in an attempt to make some 'shoulder stabilisers' for R5. But first drilling attempt didn't go so well. Will see if i do any better using works pillar drill tomorrow. Failing this, I'll make them out of scrap aluminium bar in work. This would also save on having to spray them silver!

Got in work early this morning to be able to do some more milling of the centre vent....... but someone else was setting a job up on the Milling machine! How inconsiderate lol :-D

So won't be able to carry on with that till next week now :-(

So lunchtime, I'll see if I can machine up parts of the stabilisers out of aluminium.....

Got in work early this morning to be able to do some more milling of the centre vent....... but someone else was setting a job up on the Milling machine! How inconsiderate lol :-D

So won't be able to carry on with that till next week now :-(

So lunchtime, I'll see if I can machine up parts of the stabilisers out of aluminium.....

May 04, 2011

Front Vents - machining part 1B

May the 4th Be With You...........

Sorry, but it had to be said :-)

Lunchtime I squared up the first part of the Vent with second part blank behind it, so as to be able to machine them together. With limited time, I managed to machine off enough to be able to re-set them up to carry on machining on Friday.

Sorry, but it had to be said :-)

Lunchtime I squared up the first part of the Vent with second part blank behind it, so as to be able to machine them together. With limited time, I managed to machine off enough to be able to re-set them up to carry on machining on Friday.

|

| machining the two blocks for one vent |

|

| And what it should look like when finished. |

May 03, 2011

Front Vents

Found some material large enough to make up the centre vent surrounds. Unfortuantly they weren't deep enough. So will have to machine up a pair together and then fix them together.

The main parts that will be seen are of course the front face, outside edge that prodrudes out of the skin and the internals. So I'll machine a protruding lip and machine out the inside hole area.

The main parts that will be seen are of course the front face, outside edge that prodrudes out of the skin and the internals. So I'll machine a protruding lip and machine out the inside hole area.

|

| Outside diameter shown,black marker. The 'tab' on the side will be inside the body, connecting the two parts together. |

May 01, 2011

Coin Slots - assembled

Thursday in work, I finished off the coin slots. Drilled holes in the pre-marked backing plate. Then positioned the centre lines on the backs of the coin slots under the holes and using a pillar drill, dilled into them. I then hammered in 'sel-lok pins' through the plate to secure the clots in place. Then I peened the pin ends over to secure. Not a pretty sight lol, I'll cover these over later.

Friday I was out with the family at a local event to watch the Royal Wedding. But in the back on my mind was a nagging thought. Were the base dimensions correct???

So that evening, I had to reassure myself that I had drawn them up in the correct position, as everything get's built around these!!

PHEW!! They were. Also the arms I' marked up, also fitted (length). It's one thing to follow a set of plans, but following more than one with a few 'modifications' thrown in, makes things......... interesting lol :-D

Friday I was out with the family at a local event to watch the Royal Wedding. But in the back on my mind was a nagging thought. Were the base dimensions correct???

So that evening, I had to reassure myself that I had drawn them up in the correct position, as everything get's built around these!!

PHEW!! They were. Also the arms I' marked up, also fitted (length). It's one thing to follow a set of plans, but following more than one with a few 'modifications' thrown in, makes things......... interesting lol :-D

Subscribe to:

Posts (Atom)