R5's outer feet were built, as most peoples are, to spec, well mine were as close as lol.

With a single motor wheel and caster at front to ballance, the wheel/foot assembly, then requires ankle locks to help stop the front caster from tipping the foot (due to its diameter being smaller and often 'digging in' where a larger diameter wheel is be able roll across a hole/gap). With how my outer feet and internal frame work is the locks are not the greatest, well, they're ok flat smooth surfaces, but anything slightly uneven and the 'panic stations mode' is flipped!

So the plan is to change his internal feet to better support driving him, real world situations, hopefully, reducing the worry of him tripping over.

Recent event's have confirmed that the casters are definitely the week point on any surface other than flat & smooth! So am drawing up some ideas on how best to fully lock the feet, whilst trying to keep things atheistically pleasing to the eye.

With R5 putting his [outer] feet up, I needed to replace his centre foot wheel. This may also need a future upgrade, but for now, just a new wheel was needed. The size I wanted I could only find at the original place I had got the first one from, B&Q!

The original one has worn down and although a harder compound wheel would be more suitable, the size to fit in is the limiting factor. I am looking into similar sized scooter wheels as they're material is harder, so won't wear out as much! [W.I.P.]

Spent

bout 45 mins, looking for suitable size/thickness wood, figuring out how to best fit

it..... When I found some metal strips that would be perfect. So bent one to the angle required and then marked for cutting.

I found a pair of M10 cap head bolts that should do the job of holding the

angles in place. I just need some nylock nuts.

Droid Builder

Extra Projects & Event Page's

- Home

- Trading Card Dispenser (NEW version 3) - TCD [2020/2022]

- Trading Cards

- R5-D4's ....Bad Motivator development

- R5-D4 - silver neck details

- R4-D4 - Dome [wood build]

- R0-D4 Dome [wood build]

- 3D Printing

- *** Star Wars Shoes ***

- GOUD-4 Messenger Droid - Solo ASWS

- Event: Mshed Bristol 2025

- Event: Mshed Bristol 2024

- Event's 2018

- Event's 2017

- Event 2016 - "Celebration Europe"

- Event's 2015

- Event 2014 - Chippenham Sci-Fi

- R5-D4 - events page - The beginning (2013)

- ** R5-D4 patch **

- R5-D4 Photos

- Costume for my Son - Han Solo -

- Costume for my Son - Boba Fett

- Droid Caller - Han Solo style

- Scanning Crew Container - Transmitter Storage Box

- Stormtrooper - me

- Rogue One - trading card storage box

- Rogue One

- Jabba’s gate prop for Celebration 2023

- Treadwell Droid - WED-15-77

Showing posts with label motor belt. Show all posts

Showing posts with label motor belt. Show all posts

September 02, 2015

November 26, 2014

Outer feet - weight reduction 1.1

Re-assembled all the components into the inner foot frame. I used loctite on the bolts that hold the motor in place. Then after locating the drive belt, re-fitted the rear wheel, along with its upgraded spacers and washers. Looks and feels so much better :-).

Lastly I fitted a black front caster. It needs to be lubricated as isn't very free moving.

Before assembling I did weigh the frame and it is slightly lighter..... lol :D

R5's outer feet casters were white and were only used as I had swapped them over from the the feet internals that allowed R5 to be pushed around on. This one has now been changed to a black one, need to buy another one, so I hope, they will not be as visible.

November 23, 2014

Outer Foot No.2 - Bolt locking issues

This afternoon I removed the internal motor frame from the shell, with the intention of stripping it apart to carrying out the weight reduction process as for frame no.1, only to find it wouldn't come apart? On looking inside I found one of the motor bolts had come loose! I managed to get the internal frame out and found that the other two bolts were loose.these do have barbed locking washers, but I think I may have to apply some loctite thread lock!

November 21, 2014

Outer feet - weight reduction 1.0

The internal metal frames for R5's outer feet, are heavy! They weigh 3.5 Kg each without the shell or battery box. And once the motor and wheel is removed, 1.5 Kg.

So I started looking at where material could be removed to reduce weight, though I don't think this will actually make much if any difference??

Finished the first 'wave' of cutting and weighed it....... unable to give a reading, lol.

So back on the milling machine to remove more metal :)

So I started looking at where material could be removed to reduce weight, though I don't think this will actually make much if any difference??

Finished the first 'wave' of cutting and weighed it....... unable to give a reading, lol.

So back on the milling machine to remove more metal :)

July 21, 2014

R5's got new shoes..... (Feet motor's are fitted)

Reassembled internals on foot no1. Motor, belt, wheel, then into foot shell and locked in with the aluminium channel strip. I then fitted back onto R5's ankle.....

Ooops, I forgot that the securing ankle bolt needed to be cut short. It was

that long to go through two pieces of 18mm thick wood!

Next problem I found. The gap between the side channels is slightly to

wide and there (rightly so) is no flex of give in the metal channel plates. So the ankle bolt doesn't force

the side channels to clamp onto the legs ankle. Again, the wood in the old internals did flex to clamp.

Lifting the body showed that the new foot is well balanced. But because the

foot is not clamped I need a lock....an ankle lock. So out came the paper and

pencil and traced up a wedge. Now because my foot shells are wood, the only

place I can apply the wedge, in the hope it will work and not damage the shell,

is on the inside face of the leg, so that the force is transferred to the metal motor

frame directly below it.

And here it is, screwed in place. Let's hope this works......?

YES, it works! Well in lifting the foot and trying to tip it forward it stops it doing it.

Just have to see how well once fully operational.

And here are both new feet fitted, with there locking wedges.

July 16, 2014

Outer Foot No2 - New foot internal frame work 1.3

Well, due to work commitments, welder Neil's was not been able to weld up the foot frame last week, so still waiting for this to be done.

In the mean time I got on with making the angle brackets to fit the front caster onto. I cut up some U section aluminium and then cut one of the U's off, to make an L shape. Then it was just a case of marking, drilling and thread tapping holes.

Excuse the colouring in the picture, but the Sun was streaming in through the window :)

Neil got the first part of the welding done and it's a lot less cleaning up than the other one lol.

Test fitted motor and wheel with belt back into frame......and again, there's a slight misalignment grrrrrr :( This may just be down to me and not making holes 'clearance' holes lol. Soon sorted though. Next was sorting and positioning the channel wall's, see pictures below.

Ankle bolt locked in place first to help align the two holes, then holes were drilled and tapped for the angles to support the side channel walls. Next up these and the nut to be welded.....

Neil got the first part of the welding done and it's a lot less cleaning up than the other one lol.

first part of welding, done

Test fitted motor and wheel with belt back into frame......and again, there's a slight misalignment grrrrrr :( This may just be down to me and not making holes 'clearance' holes lol. Soon sorted though. Next was sorting and positioning the channel wall's, see pictures below.

Ankle bolt locked in place first to help align the two holes, then holes were drilled and tapped for the angles to support the side channel walls. Next up these and the nut to be welded.....

July 09, 2014

Outer Foot No2 - New foot internal frame work 1.2

This morning I got on with drilling and tapping holes to fit the angles onto to help locate the channel plates for welding.

Welder Dave is away, so hopefully welder Neil will be able to weld this all up tomorrow.

July 08, 2014

Outer Foot No2 - New foot internal frame work 1.1

Marked up and drilled holes for motor bolts and the large hole for the motor to fit through, see below.

Cut up two scrap pieces which will be welded across the to side plates.

Fitted a location bolt to aid welder later on. Did some more work on the two channel wall pieces. Drilled the main bolt location holes and have started on the angles to support the sides for welding up.

Cut up two scrap pieces which will be welded across the to side plates.

Fitted a location bolt to aid welder later on. Did some more work on the two channel wall pieces. Drilled the main bolt location holes and have started on the angles to support the sides for welding up.

July 03, 2014

Outer Foot No2 - New foot internal frame work 1.0

Foot No2.

I marked and cut out a piece on the outer foot shell.

I then started on inner foot frame no2.

Metal plate, marked and cut out.

Metal plate, marked and cut out.

Next, to mark up the metal plate for drilling holes.

July 02, 2014

Outer Feet - New foot internal frame work 1.7

Test fitted the 'new' foot build on the leg. All fits well and looks good.

Just need to fit front caster.

Fitting the front caster.

I marked up some aluminium angle and drilled 5mm dia clearance holes in it. I then tapped out two holes to M5 threads and secured the angle in place.

I didn't have to but thought it would make life easier to remove the excess metal from the

side plates, below the angle. I also have some M5 hex socket head bolts/screws

on order, as my 'supply' has now run dry ;D

side plates, below the angle. I also have some M5 hex socket head bolts/screws

on order, as my 'supply' has now run dry ;D

June 27, 2014

Outer Feet - New foot internal frame work 1.6

For my Wood internal wheel frame, I used T-nuts to be able to clamp the leg ankle to the foot internal. This was a great idea as it ment I didn't have to (somehow) reach inside and try to secure the bolt to the nut.

Now I have metal frame work, this requires I get a nut welded to the back face.

Here is the finished frame, just need cleaning up the weld splatter. Thanks Dave, great work!

Aluminium angle and bolts can now be removed.

I will need to cover/fill/block up the threaded holes visible inside the side channel plates.

I also needed to re-drill a hole location for the lower aluminium channel plate.

One was a new hole due to the location of the new metal frame internals and the old hole would need to be blocked up. So I decided to just make up a new strip as the old version I wasn't to happy with how it looked or would of looked with the blocked hole.

So I drilled & countersunk two new holes.

Secured with these hex socket countersunk bolts off eBay :)

Sorted out the axel bolt holes and reduced the brass motor bolt bush's my 1.6mm.

This helped alignment of the belt with the wheel more.

Next up is to fix the front caster back on. This is a stabiliser to keep the foot level.

Measured up the inside, this is bacause the metal flexed a bit when it was welded.

These are just gude measurements ;-) lol

Next is to fit the front caster on, then it's on with frame work for Outer Foot No2.

June 23, 2014

Outer Feet - New foot internal frame work 1.5

Back in work to drill the holes. The three 5mm dia clearance holes for the Motor plus a centre drill point to help line up the other plate. Then using a drill and a boring tool, I got to work on opening out the hole to fit the back end of the Motor through.

Well, the hole alignment between the two main plates for the wheel axel, were off......only a bit but enough for the belt to be so tight it tipped the axel and the other end wouldn't fit through the hole in the other plate! The hole in the side plate for the back end of the motor to fit through, helped align it, so I opened up the holes a bit.

I got Dave in work to weld up the frame.

When I got home Friday, my two axel bolts had come. Once I'd fitted it all together, it looked like this.

The last picture (above) also has the first channel wall piece. These wont be welded on (for now) as I'll need to sort out clamping of the leg and also how best to support the Outer Foot shell to the internal motor/wheel frame.

Next job then was to locate the first channel wall piece. I drilled and tapped into the Steel frame & the channel wall piece.

To be continued......

Well, the hole alignment between the two main plates for the wheel axel, were off......only a bit but enough for the belt to be so tight it tipped the axel and the other end wouldn't fit through the hole in the other plate! The hole in the side plate for the back end of the motor to fit through, helped align it, so I opened up the holes a bit.

I got Dave in work to weld up the frame.

When I got home Friday, my two axel bolts had come. Once I'd fitted it all together, it looked like this.

The last picture (above) also has the first channel wall piece. These wont be welded on (for now) as I'll need to sort out clamping of the leg and also how best to support the Outer Foot shell to the internal motor/wheel frame.

Next job then was to locate the first channel wall piece. I drilled and tapped into the Steel frame & the channel wall piece.

To be continued......

June 19, 2014

Outer Feet - New foot internal frame work 1.4

I had two choices:

- To modify the internal wood frame work to accept the new wheel and motor arrangment. Wood/Metal hybrid?

- To build a new metal 'frame' based on design's already used by other builders?

Neither is a quick solution.

Am going to go with new metal internal frame works. Going to follow, attempt to follow, a now tried an tested method of assembling a 'flat pack style' frame work.

For more details, see Astromech.net.

So I ordered some metal plate as a starting point. 300x300x3mm thick.

Above pic is sheet 1 of the two bought. I then made a carboard template and worked out best position for the wheel and fixing bolts.

I needed some spacers to fit between the wheels and the side plates.

So turned some up out of Brass bar.

I didn't fancy replacing these at a later date and the bar was to hand.

To reduce some of it's weight I turned a step diameter to produced 'flanged' ends.

M8 x 80mm long bolts are ordered for the main wheel's.

Next I got out my (my Dad's) angle grinder, that I 'borrowed/was lent' about 15 years ago lol, and got to work cutting out the sections. For my first attempt's at cutting, and comments I've recieved, I didn't do a bad job of cutting straight edges!

In work I used the piller drill to drill accuratly the two holes for the main wheel bolt.

I used the works guillotine to cut two strips which will be welded across the top,

to the sides to form a box section.

to the sides to form a box section.

After measuring the distance between the wheel and gear on the motor, I marked an arc from the centre of the wheel bolt. This helped me to determin the best position for the motor to fit inside my Foot Sheel. As there's not much room. I roughly marked an opening area on the inside face of the foot shell and cut it out.

Next is to drill holes, but that's a 'back in work' job......

June 09, 2014

Outer Feet - motorisation is on its way 1.3

Well, the wheels did NOT arrive last week as I had hoped, so was refunded via eBay. Some more were found and were soon be ordered.

Scooter wheels link

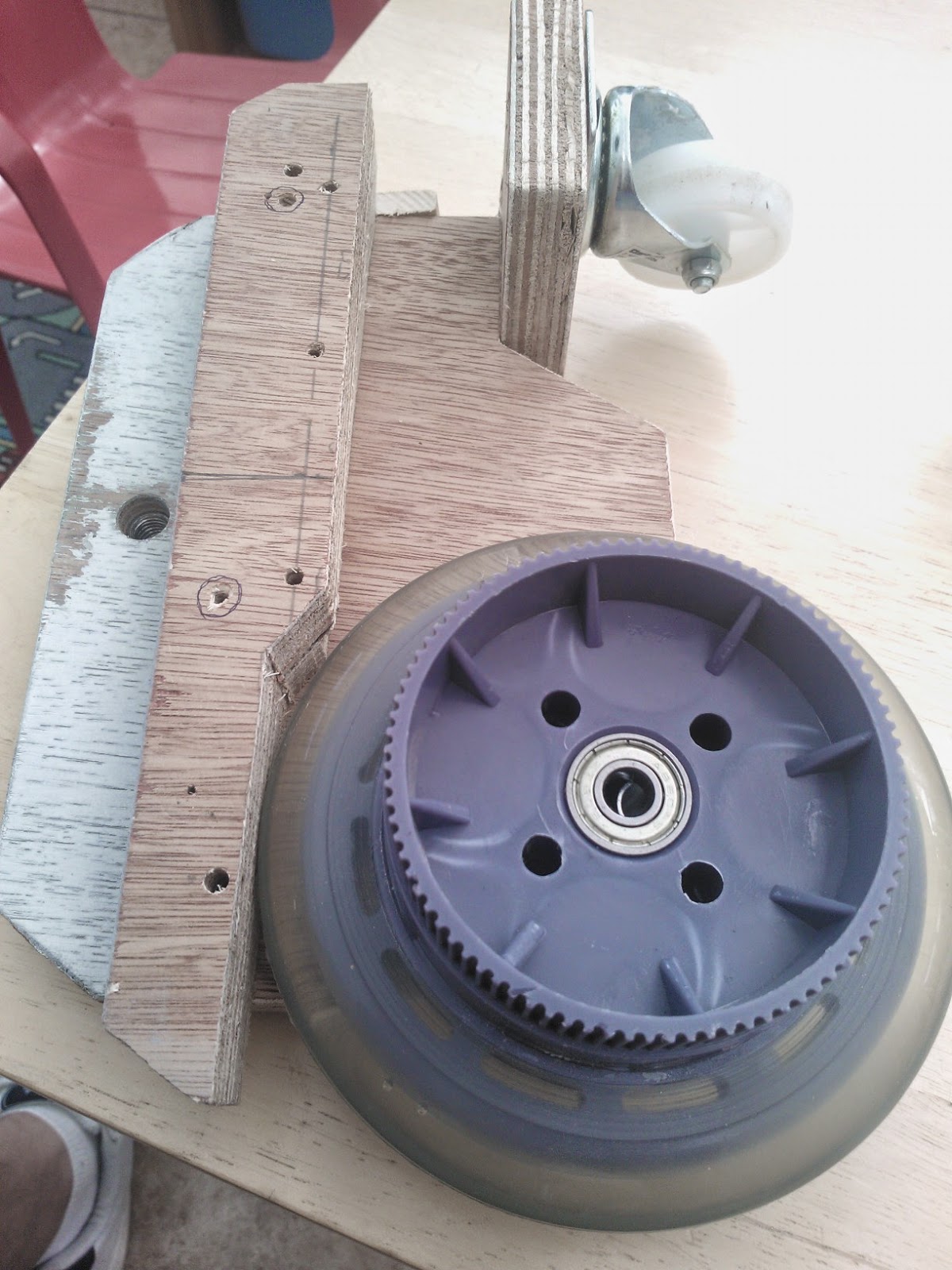

My Son was just as excited they had come as I was. So we both headed out to the garage to work on removing the 'brake drums' which we won't be needing.

These are held in place with four metal pins. I opened up the vice jaws and rested the wheels on the opening. We then got to work with a hammer and screwdriver to hit the pins out from the other side.

The four pins can be seen in image above.

Here is what I am faced with next though....

Apart from the increase thickness, they are also slightly larger diameter than the old scooter wheels, so internal upgrade WILL be required. Design process engaged!

I also thought at first that my belts were too short as the motor was quite close to the wheel, but on second thoughts this might not be a bad thing as space is limited inside and also the position of the motor means it has to be fitted/covered by the battery box once all installed.

Scooter wheels link

My Son was just as excited they had come as I was. So we both headed out to the garage to work on removing the 'brake drums' which we won't be needing.

These are held in place with four metal pins. I opened up the vice jaws and rested the wheels on the opening. We then got to work with a hammer and screwdriver to hit the pins out from the other side.

Here is what I am faced with next though....

Apart from the increase thickness, they are also slightly larger diameter than the old scooter wheels, so internal upgrade WILL be required. Design process engaged!

I also thought at first that my belts were too short as the motor was quite close to the wheel, but on second thoughts this might not be a bad thing as space is limited inside and also the position of the motor means it has to be fitted/covered by the battery box once all installed.

May 09, 2014

Outer feet - motorisation is on it's way 1.1

Whilst waiting for my wheels to arrive, (over a week now!) I've been swotting up on build designs for R5's motorised feet. Also been sourcing material for the new internals. I found some scrap brass bar which I machined up to use for spacer tubes for the motor fixing screws. These can be seen bottom of the pic. The motor has a post-it on it for hole location transfere checking.

I'm planning on having a go at modifying my original internal frame to accomadate the motor and new wheel. The metal plate strip I'm planning on using to locate the new wheel's axel.

I'm planning on having a go at modifying my original internal frame to accomadate the motor and new wheel. The metal plate strip I'm planning on using to locate the new wheel's axel.

Subscribe to:

Posts (Atom)

![first part of welding [& caster bracket] R5D4](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgjSsrjEYnKaW2bUORvQu5QPCYNpdmwGT48Z5LQY_A-DBg-ywGZ0ixK5qI_pBiC_P8KW5v7Wemp1CKo2rCNafMOoTSI50yKI_DiWuoM2Obwv6sXS-eZaBxukgbbAjnmEIJnskL5W-QXpc8/s1600/New+wheels+No2+-+WP_001764.jpg)