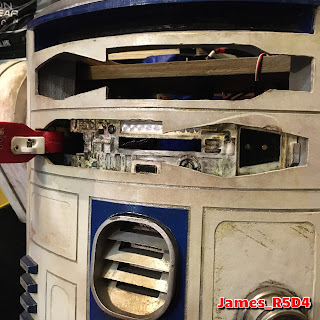

Plans and more plans as this build takes shape.

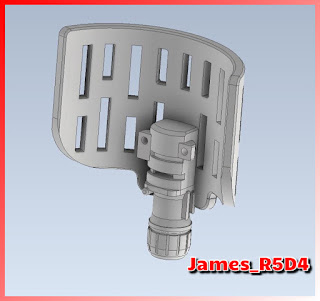

Had the idea of toothed belts for the lift system, but that wasn’t a simple option, it would require more components. Then I thought about a pulley system. Found a servo that was broken, swapped out its plastic gears for metal ones & removed the signal wire. So it’s just a power motor.

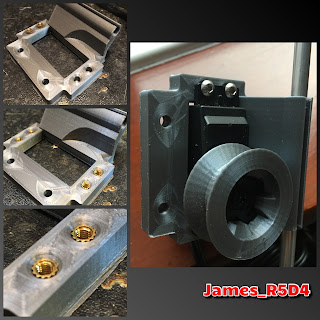

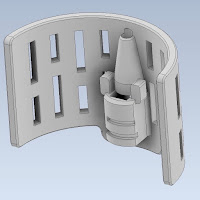

Next up was to design a holder for the servo/winch, that also combined the tube sleeve holder. I kept the slot in the sleeve so that there is some allowance for printing tolerance.

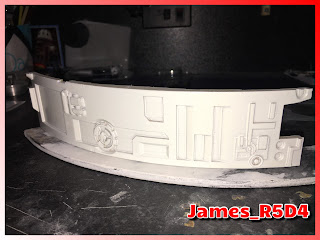

This was a test print, but isn’t far off the finished part. The curved part is for clearance of the winch wheel, this I downloaded off Thingiverse from Tetrix 'large Servo winch' (link). I’ve placed it so that it’s inline with where the bottom location point at the tube end will go.

I’ve left space for mounting this at a future date to the inside of the dome.

......yep, design has been updated, less material where not needed, additional added along with holes for fixing of the servo and for the unit to be attached to the dome insides. Had a thought about how best to connect the servo screws, so went with.....

........Brass threaded inserts.I’ve also drawn up and printed a bottom servo holder for rotating the LFC. And I found some wire that could be used for the mast.

Still waiting on the micro switches to arrive, then update no3 will possibly include a location for them to be mounted on with.

Have also ordered some other goodies.